- 제품소개

-

오늘보다 더 나은 내일, 풍요로운 미래를 위해 땀 흘려온

현대하이켐이 행복한 미래를 만들어 갑니다.

Change IR Heat agent

SUN-13

| Stability | SUN-13 is APO-free product which does not make influence on the environment. It is non-formalin product which can be used in fabric processing. |

|---|---|

| Composition | Conductive metallic oxide compound |

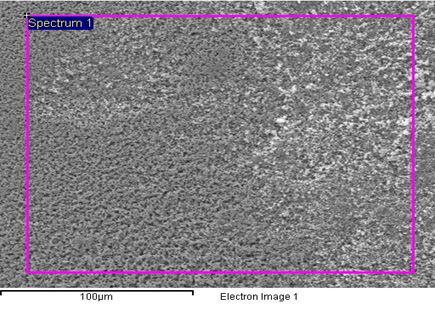

| Revelation | Appearance : Blue dispersion liquid Solid content: 11 ± 1% Ionic character : Amphoteric ion pH : 6.0 – 8.0 Particle(D50, D90) : Less than 150nm, less than 200nm  SEM image of the raw material

|

| Expiry date | 6 months after manufacturing date |

| Immunity notice | The above reports are the results from our laboratory and it does not guarantee the working at actual site certainly. |

| Manufacturer |  |

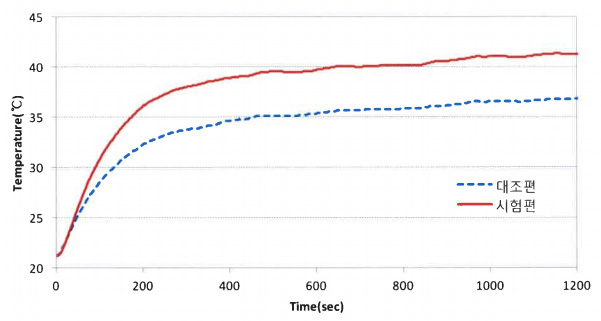

Example of padding application result

| Application fabric | General (Water non-repellant) fabric |

|---|---|

| SUN-13 use amount | 3% ows |

| Binder use amount | 1.5% ows |

| Padding method | 1DIP1NIP |

| Coating amount(Wet pick-up) | 50-80% |

| Drying condition | 150℃ * 5min |

| Optothermal test result | Higher average 4.5℃ for 1 minute than blank. |

| * Optothermal test method | Ventex in-house method |

Test conditions

| Standby state | (20±2)℃, 65±5)% R.H. |

|---|---|

| Lamp used | Iwasaki 500W lamp |

| Distance between lamp and specimen | 50cm |

| Test time | 20min |

| Specimen size | 10cm * 10cm |

Recommended not to use this chemical for the antifoulant processed fabric because the inflammability performance is reduced when it is processed.

Use this chemical after verifying certainly because it can reduce the fastness such as light resistance, heat resistance, water sign, whitening, chalk mark, discoloring, rubbing coloring and embossing depending on the treatment methods.

Perform the post processing (Embossing and etc.) of this chemical certainly after verification.

Check the compatibility and stability fully in case of mixed using with other chemicals.

Keep certainly under the room temperature because it can be frozen in case of keeping under -4℃.

Seal with the cap certainly during or after use.

This chemical is a product made by making the metallic oxide in nano scale. Use after checking the hardness of water certainly because ion shock trouble can be occurred by meeting of the hard water or the anion from the underground water metal like 2+(Mg2+, Ca2+) and negative charge on the metal surface.