- 제품소개

-

오늘보다 더 나은 내일, 풍요로운 미래를 위해 땀 흘려온

현대하이켐이 행복한 미래를 만들어 갑니다.

Non F Soil Release agent

HD GUARD NF100

It is optimized non-fluoric water repellant for cotton and various synthesized fabrics. It can be used conveniently at production site as it contains the cross linking agent basically. More excellent washing durability can be granted by adding exclusive cross linking agent before processing treatment.

It is available to use on heat sensitive fabric as it can be used in drying temperature of 140-150℃.

| Stability | HD GUARD NF100 is environment friendly product not containing PFOA and PFOS which are regulated for environment issue. |

|---|---|

| Revelation | Appearance : Milky white emulsion pH(10%) : 4.0 ± 1.0 Ionic character : Weak Cation Specific weight : 0.99 ± 0.01 Solubility: Easily soluble into cold water |

| Expiry date | 6 months after manufacturing date |

| Immunity notice | The above reports are the results from our laboratory and it does not guarantee the working at actual site certainly. |

| Manufacturer |  |

Example and result of padding process application과

| Application fabric | Cotton 100% |

|---|---|

| Chemical | HD GUARD NF100 50g/l (Non-fluoric water repellant) FIXERNOL BZ-9 10g/l (Cross linking agent) (The amount of the cross linking agent is controlled by the touch or performance wanted.) |

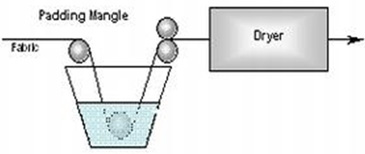

| Processing condition | Padding method (1Dip1Nip) |

| Coating amount(Wet pick-up) | 70 – 80 % |

| Drying condition | 170℃ *15m/min (Based on tender 4chamber) |

| Water repellant power evaluation after 20 times of washing (KS K ISO 4920:2014– Spray method) | Grade 4 |

| Antifouling property evaluation after 20 times of washing (KS K 0610:2011) | Grade 4 |

| Measuring contact angle after20 times of washing (KS L 2110) | 142.4℃ (Corresponded to the high repellant based on contact angle evaluation as it is higher than 140 degrees) |

Reduce or increase the use amount depending on the water repellant level or durability.

The wanted water repellent power and durability can be obtained by processing to remove penetrant on the fabric standby for processing or the surfactant remained during dyeing completely.

The performance and compatibility shall be considered in case of using the softener for touch. The water repellant power and durability can be reduced in case of using together with the softener.

Prohibited to use by mixing with anion product because its ionic character is weak cation.

(Probable to occur the gum up due to ionic trouble)

The problem from the product stability is not occurred when the pH of the padding tank is maintained in 5-6.

The water repellant power can be reduced a bit when the fixing agent is used by using the reactive dye after dyeing.

Color fastness to sublimation can be reduced when the water repellant is treated on the fabric dyed with dispersion dye. Use by selecting the dye which is excellent for color fastness to sublimation

Decide the use amount after performing appropriate pre-test because it can be differed by the fabric type and physical property requirement.

Keep by sealing without contacting to the air at 5~35℃ and avoid the freezing and high temperature.

Seal during and after use certainly.